The Creation of True-Load

Table of contents

Tim Hunter has the Word

Hi, I’m Tim Hunter, founder and president of Wolf Star Technologies and the creator of True-Load. I would like to tell you a little about the struggles and triumphs I encountered (and overcame) in my engineering career and how that led to the creation of True-Load. Yes, before I was a software developer I was an engineer, just like you. I started out my career quite a few years ago (thirty to be exact) at Harley Davidson.

Harley Davidson Innovations

At the time I was the lead Senior Project Engineer for Frames and my team was responsible for the design of the motorcycle frame. Tools to measure loads on the frame did not exist, yet our team was tasked to produce FEA results that were meaningful and impactful to the design.

As is typical with product development programs, the timing is so compacted that test results from the previous prototype level aren’t available to inform the next prototype level. We were in the middle of a 1 million dollar design intent build of prototypes at the plant when I received a phone call from the proving grounds.

Wake up Call

The test technician said, “Tim, you have got 4000 microstrain on the downtubes. All of the frames you are building are no good,” I had the difficult task of telling the platform director and VP of engineering that we had to push the program back a year because of high strains in the frame. The VP had to tell rest of the company that we needed to push the product launch back a year.

This was all due to not understanding the loading on the frames and there were no tools to give me the complete loading to understand the proving ground events. I kept thinking there had to be a better way. And my company was counting on it. I scoured through formulas for countless hours until I realized the answer was right in front of me the whole time. If I could just consistently tap into it, I could enable my team to save H-D millions of R&D dollars and eliminate complete iteration cycles.

Creating True-Load

Like you, I was trained as mechanical engineer and I knew I was onto something big. I recognized that I needed to fine-tune my eureka procedure and turn it into software that EVERY engineer could use to solve their own unique problems, no matter what industry or product they were developing. So, I taught myself to code and wrote my own software program, which today is known as True-Load.

With the first incarnations of the True-Load procedure I was able to match proving ground strains within 2% in the most difficult region of the frame to correlate (the fender supports with luggage). In 2010, after twenty-two years at H-D I decided it was time to start my own company and package True-Load in a form that can help engineers all around the globe, who were experiencing the same problems I had been throughout my career prior to my eureka moment.

Customer Creations

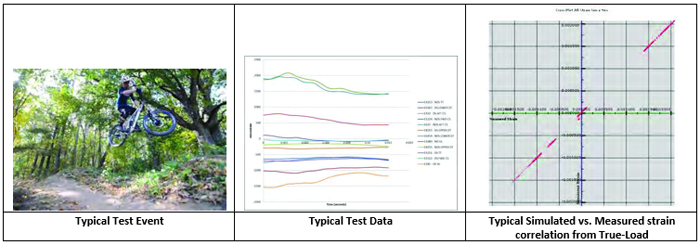

Here are few examples of published information from our customers. The first example is from Jay Maas at Trek bicycles. Trek uses True-Load to understand complex loading on their frames. Jay wrote about how they could capture severe loading from jumps in 2015.

Next is an example of testing performed by a SAE Baja team student group from the University of Wisconsin. The students turned the suspension arm of their Baja car into a load transducer using True-Load. They then used the measured loading to drive fatigue calculations with fe-safe. The students were able to reduce the weight of their suspension arm by 25% without compromising the durability of the arm. This all documented in the SAE paper 2016-01-0429. It should be noted that these students have never done any real FEA modeling; never touched a strain gauge; and never done any data collection. They did the entire project (with my coaching) in 6 weeks.

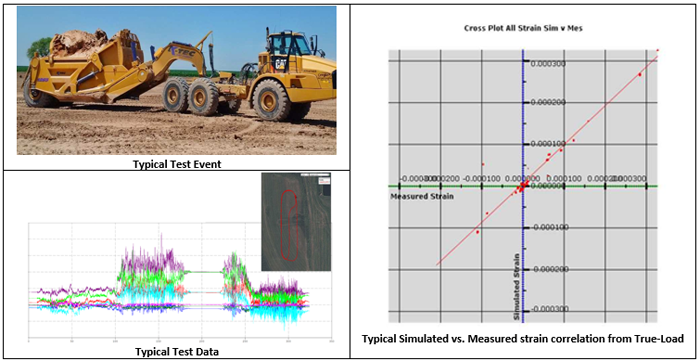

The last example here is a K-Tech earth mover from a paper presented by Wayne Tanner and Cynde Murphy of Adaptive Corporation. In this project the operating loads on the earth mover are calculated. An interesting result of the study showed that the most sever loading on the earthmover occurs in transit and not during digging operations. This was totally counter intuitive to the engineers at K-Tech.

Discover TECHNIA’s PLM Solutions